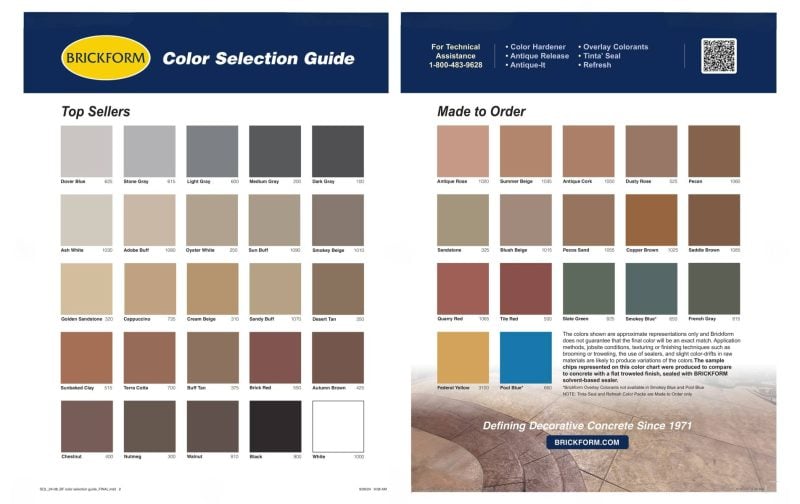

Concrete Color Hardener

Brickform uses the highest quality UV-resistant pigment, sand, and fine aggregates to manufacture their Color Hardener. Perfect for stamped concrete and trowel finishes, concrete Color Hardener produces consistent and brilliant color while standing up to abrasion, weather, and normal wear.

Find A Distributor